Working in the food industry, you have to be very aware of the high standards for hygiene and cleanliness. Big product recalls or, even worse, contaminated groceries not only cause big financial losses for the respective company, but also a huge damage to their credibility, trust and image. That is why Envases Öhringen, as a competent partner in this industry, has developed extraordinarily secure concepts and guarantees that each and every product that leaves the fabric lives up to their self-imposed standards. That is no different for the hygiene measures of the 5-liter kegs Envasis produces.

Hygiene for 5-liter kegs: made out of impeccable resources

To produce quality kegs, Envases uses numerous high-grade resources. Tinplate, finishes, rubber and various plastics – all together they form a mini keg. As soon as a resource is used at Envases, the company tests it first in terms of its food regulatory harmlessness. That is why all suppliers are obliged to prove that their products are officially conform with EU regulations. Not before this document is delivered, the respective resource enters production.

Once the keg is finished, it will be checked by another, third-party accredited testing institute. The reason for this is, to make sure that not only all of the used resources are safe, but no other impairment has taken place during the production process. For example, the institute checks if some of the used materials migrated into the filling. These tests are being performed in a chemical lab by using sensor technology. It is imperative that packaging does not influence filling neither chemically nor in taste. The tests that are run in the lab are all initial tests, that take place whenever a new resource will be used.

Hygiene for 5-liter kegs: production hygiene for maximum safety

After testing the resources, it has to be made sure that the production process is being set up as hygienic as possible. There are three different types of possible contamination that have to be avoided by any cost: physical, biological and chemical contamination.

Physical contamination: foreign substance management for safe products

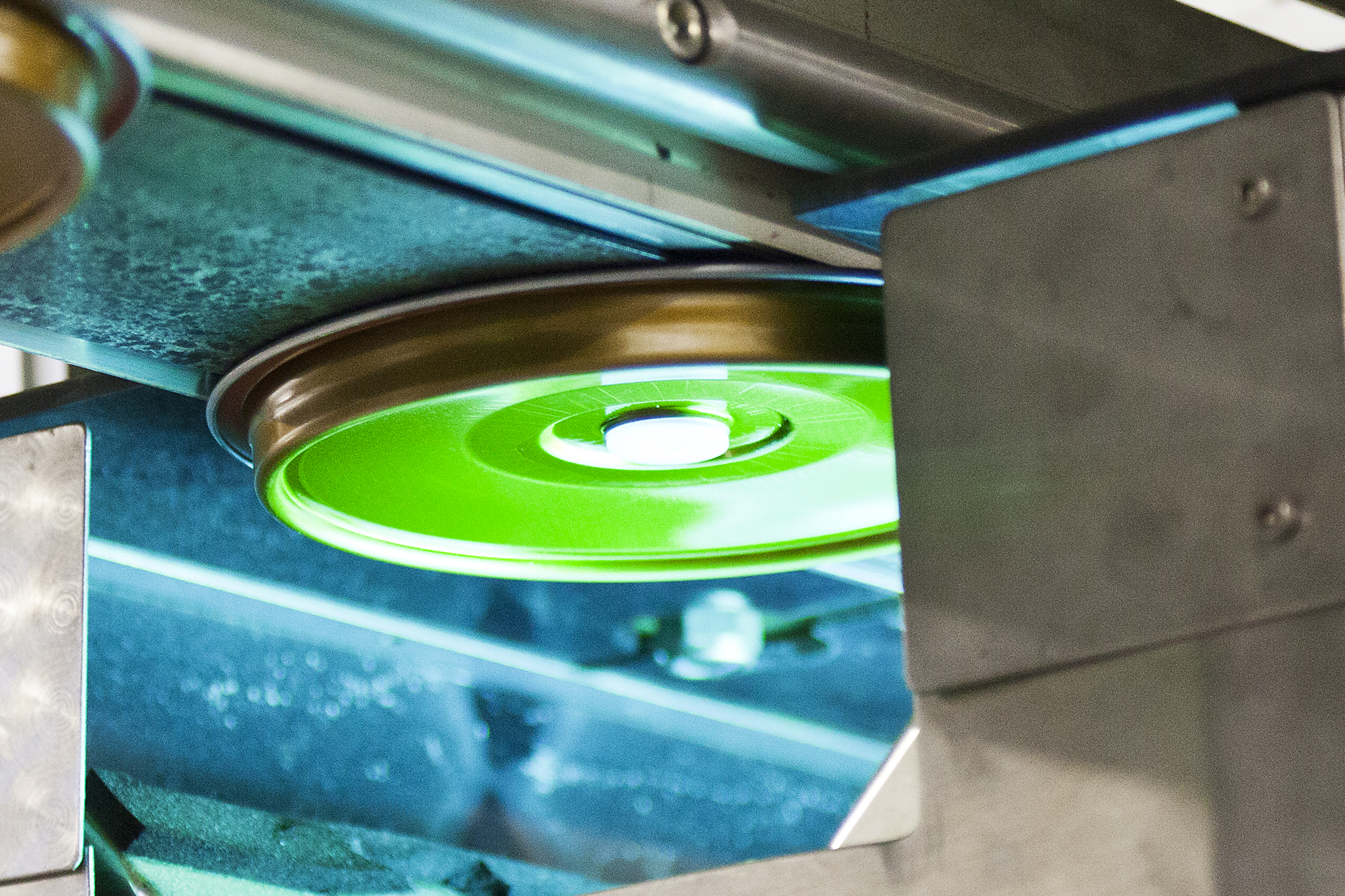

Camera screening the MiniKEGs to avoid contaminant.

Pieces of glass, screws or metal parts – how bad it would be if something like this would end up unnoticed in a 5-liter keg and be delivered to the customer! To avoid this, a lot of measurements are put in place:

- The entire production line is covered

- Before the keg is sealed, a camera checks the inside of every single keg for foreign substances

- Production workers are only allowed to drink from plastic bottles, to prevent potential risk of glass splinters

- All glasses that are being used in production are registered and are being checked regularly

- All knives are registered in a so-called ‘blade register’. In case one of the knives is defective, its being reported and sorted out right away.

- All workers wear gloves, hats, safety boots and have to disinfect their hands several times per day.

Envases not only tests the keg itself for potential foreign substances, they also have very strict regulations in place to make sure physical contamination is being avoided right from the start.

Biological contamination: battle against germs, viruses and vermins

Bacterial or viral contamination is a huge safety threat. It would have a significant impact on quality and tolerability of the filling. To kill potential germs right during the production process, all parts like top and bottom of the kegs are being irradiated by static ultraviolet light. The same procedure is being used before the lid is being installed on top of the keg. That way the whole interior part of the keg is being irradiated to kill all potential germs and viruses. That is why it is not necessary to rinse the kegs before filling them. They are produced by Envases as sterile as possible and delivered as closed systems to the customers before they start filling them. The lid, the so-called dust cap, is only being removed right before the filling process starts.

To make sure that production is as sterile as possible, there are a lot of prophylactic measures in place. There is no kind of uncontrolled air flow in the shop floor, which is also put under overpressure. That means, that the windows cannot be opened, and the doors work like air locks. Air flow is being controlled by air conditioning with very fine filters. That way the air in the shop floor is kept very pure and the climate is constant. Obviously, no food is allowed on the shop floor. Only water in plastic bottles. In addition to all these safety measures, the Technical University of Munich performs airborne germ measurements on a regular level. That is to ensure quality and effectiveness of the filter system.

Vermins like mice or insects won’t be able to get into the shop floor because of the closed production system. Furthermore, there is a specific pest control system in place, that would immediately take countermeasures in case of an infestation.

Chemical contamination: no chance for solvents and co

A third type of potential contamination are chemical substances like solvents or other fluids. To prevent this, the camera is being used aswell for the final inspection of the kegs. It takes pictures of the entire interior of the mini keg to identify the smallest droplets or moist spots. Because of the constantly controlled air flow and the fine filter system, gasiform contaminations are practically impossible.

Envases Öhringen guarantees a maximum of cleanliness for the entire 5-liter keg production. Therefore, the respective shop floor has only restricted access. It allows exclusively for employees that are familiar with the strict hygiene regulations to enter. That way human mistakes are being reduced to a minimum.

Conclusion: No matter if it comes to physical, biological or chemical contaminations, Envases Öhringen has appropriate countermeasures and a well-organized prevention system in place. That way the company ensures its customers with maximum safety and cleanliness.